Optical Brightening Agents (OBAs) are a class of functional chemicals widely used in industries such as textiles, papermaking, plastics, and detergents. They enhance the whiteness and brightness of objects by absorbing ultraviolet light and emitting blue-violet light, thereby improving the visual appeal of products. In practical applications, understanding the whitening and color development principles of Optical Brightening Agents and their detection methods is crucial to ensuring product quality and safety. This article will systematically analyze the mechanism of action, detection technology, and industry applications of Optical Brightening Agents.

What is Optical Brightening Agents

White substances generally slightly absorb blue light at 450-480nm in visible light, which results in insufficient blue, making it slightly yellow and giving people a sense of age. To this end, people have taken different measures to make items whiter and brighter . Fluorescent Whitening Agent (FWA) is an important functional additive, a colorless organic compound that can absorb invisible ultraviolet light (wavelength range between 300-400nm) and then emit blue-violet fluorescence (wavelength range between 420-480nm) visible to the naked eye, filling the color loss caused by the yellow tone on the surface of the object, thereby making the material appear brighter white.

Whitening principle of Optical Brightening Agents

Optical Brightening Agents absorb near-ultraviolet light with high energy to make their molecules enter an excited state, and then the excited molecules transition to a ground state with lower energy and emit fluorescence. Due to energy loss, the wavelength of the radiated fluorescence becomes longer, about 450nm blue light. The yellow color of yellowed objects can be compensated by the blue light reflected by the Optical Brightening Agents, thereby increasing the apparent whiteness of the objects. Since the intensity of the emitted light exceeds the intensity of the original visible light projected on the treated object, a slightly colored whitening effect is produced.

Simply put, the color development principle of Optical Brightening Agents is divided into the following two parts:

· Absorption and emission:

The molecular structure of Optical Brightening Agents contains a conjugated system, which can absorb short-wave ultraviolet light energy and release blue-violet fluorescence after electron transition.

· Color compensation effect:

The emitted blue-violet fluorescence is superimposed on the reflected light of the material, compensating for the original yellow or gray tone of the material, making it look whiter and brighter.

Factors affecting whitening

· source type:

Optical Brightening Agents work best under light sources with high UV content (such as daylight or D65 standard light source), but are not obvious under incandescent light.

· Material surface characteristics:

The material's adsorption properties, roughness and base color will affect the actual effect of the brightener.

Why should we test Optical Brightening Agents?

The use of optical brighteners plays an important role in many fields, but their detection has become crucial for the following reasons:

1. Quality control

testing of Optical Brightening Agents can ensure that products meet target whiteness standards and improve market competitiveness.

2. Safety and Regulatory Compliance

Some Optical Brightening Agents may be potentially harmful to humans or the environment (such as skin allergies, ecotoxicity).

Regulations in different industries (such as EU REACH) require restrictions or labeling on the use of brighteners.

3. Detection of counterfeiting or illegal use

In industries such as textiles and food packaging, the illegal addition of Optical Brightening Agents needs to be controlled through detection methods.

4. Environmental protection requirements

With the promotion of the concept of sustainable development, testing the impact of Optical Brightening Agents on the environment has become a key step in evaluating the environmental friendliness of products.

Methods for detecting Optical Brightening Agents

The methods for detecting Optical Brightening Agents are mainly based on their physical and optical properties. The following mainly introduces several common optical detection methods and their characteristics:

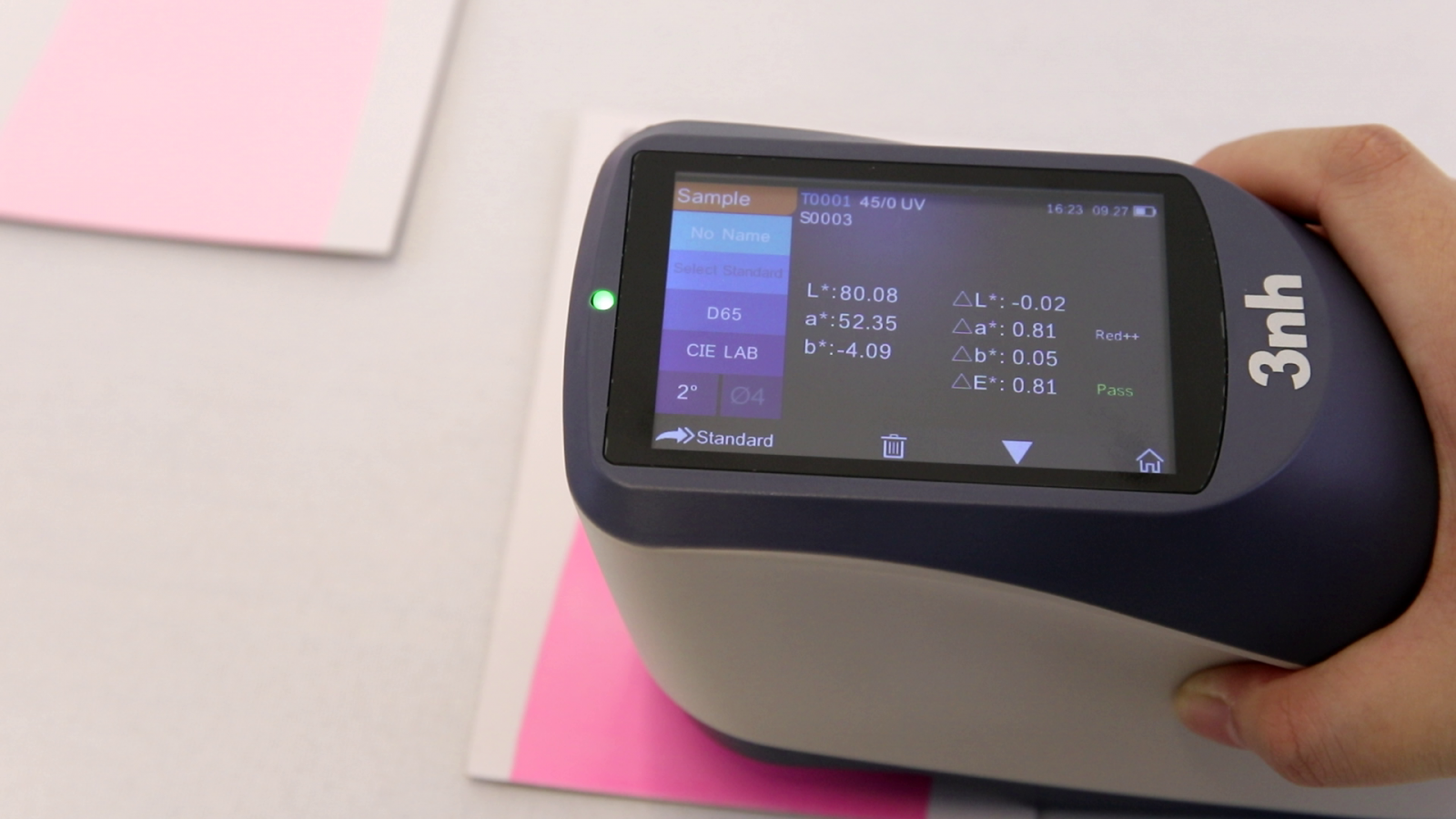

1. Spectral reflectance method

Basic Principle:

Use a 3nh spectrophotometer or colorimeter to measure the color of the sample under UV and UV-free light sources, and compare the data to separate the fluorescence effect. The emission spectrum characteristics of the Optical Brightening Agents (420-480 nm) will form a peak in the result, and analyzing its intensity can evaluate the content and effect of the whitening agent.

Application:

· Determine the uniformity of distribution of Optical Brightening Agents in different materials.

· Compare the effects of brighteners under different process conditions.

· Analyze the light emission efficiency of the brightener.

· Monitor how brighteners perform under a UV light source.

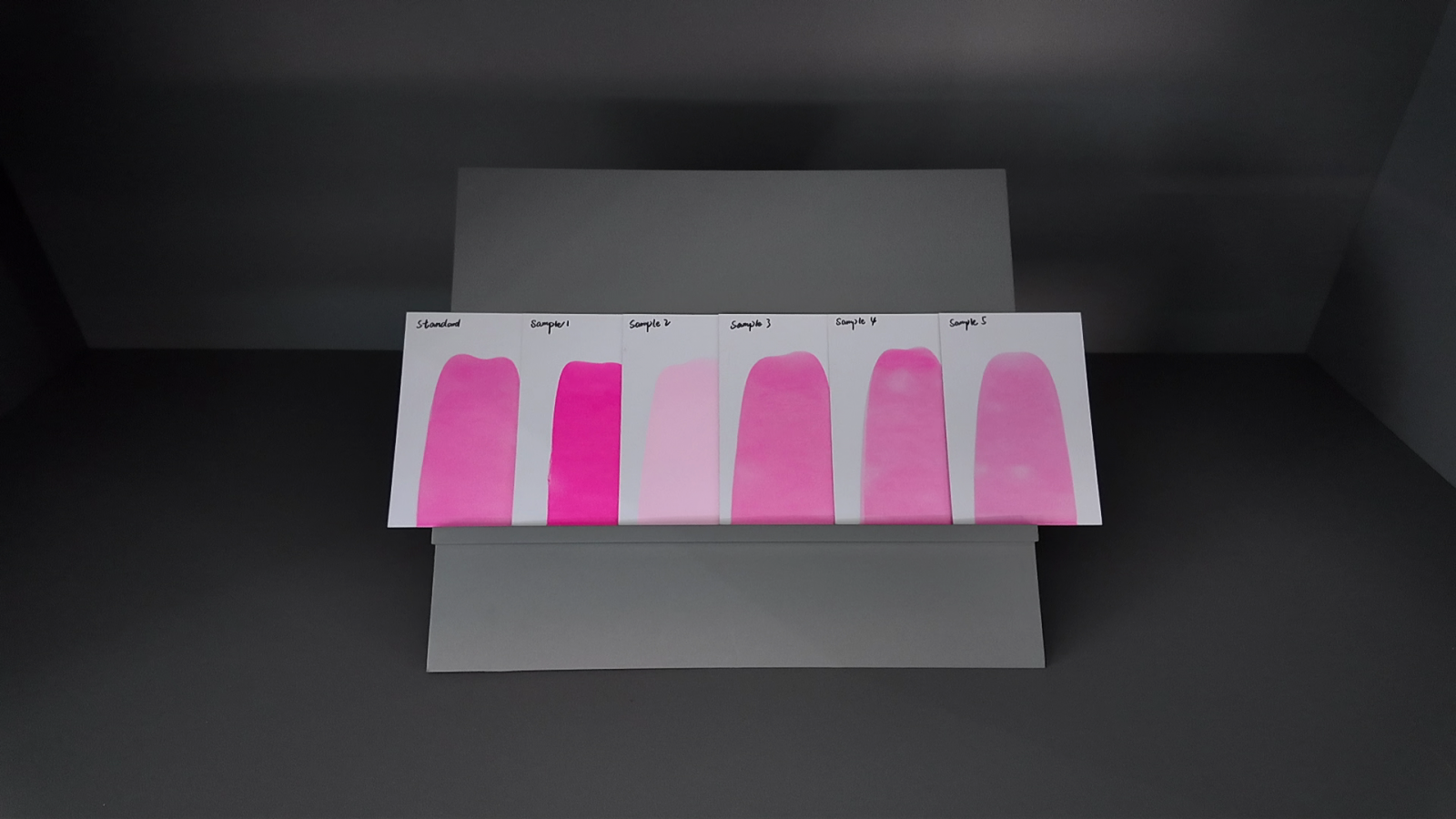

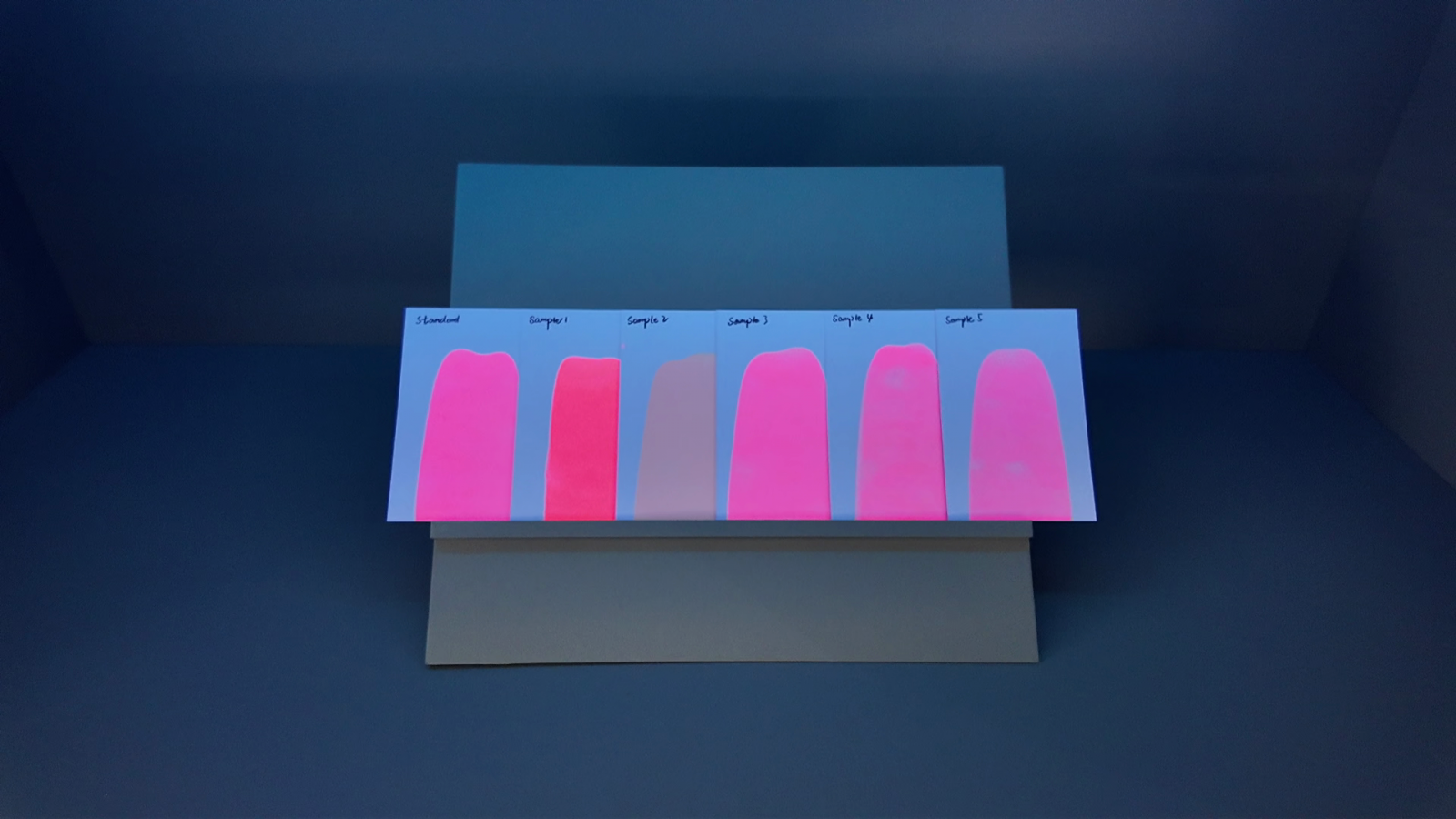

2. Ultraviolet light source irradiation observation method

Basic principle:

Place the sample to be tested (such as paper, textiles, plastics, etc.) in a dark room or a weak light environment to ensure that the fluorescence effect under ultraviolet light is more obvious. Use a standard light source to match the color light box, turn on the UV light source, and observe with the naked eye whether the sample emits fluorescence, which appears as a blue-white or blue-purple luster.

|

|

|

|

application:

· Simple and direct inspection of the presence of Optical Brightening Agents

· Suitable for initial screening and large-scale testing

· Limited to qualitative analysis, unable to accurately quantify whitening agent concentration

3. Colorimetry

Basic principle:

The chromaticity value of the sample is measured using a spectrophotometer, using the CIE Lab color space, by measuring the L* (brightness), a* (red-green hue) and b* (yellow-blue hue) values of the sample under a standard light source (such as D65). The b* value of samples containing Optical Brightening Agents usually decreases, indicating a reduction in yellow hue.

application:

· Tests the color consistency of materials treated with optical brighteners.

· Analyze color changes under different light sources.

Key Metrics:

· A decrease in the b* value indicates a less yellowish hue in the material, i.e. a better whitening effect.

· An increase in L* value represents an increase in brightness.

4. HPLC analysis (High Performance Liquid Chromatography)

Basic principle:

HPLC is used to separate and quantitatively detect the molecular components of Optical Brightening Agents, which is suitable for quantitative analysis of complex samples.

application:

· Detection of brightener residues in textiles, paper or detergents.

· Determine the purity and degradation products of brighteners.

0086 18165740359

0086 18165740359

Skype Online

Skype Online