Soy sauce is one of the most widely used condiments around the world, and its dark brown to black appearance plays an important role in many dishes. The color of soy sauce is not only related to its taste, aroma, and texture, but also reflects important factors such as its production process, fermentation time, and raw material selection. Therefore, accurate color measurement plays a vital role in the production and quality control of soy sauce. This article will explore the importance of soy sauce color measurement, influencing factors, and how to achieve accurate color measurement through 3nh.

Types of soy sauce colors

The color of soy sauce is usually dark brown to black, and the color depth reflects its fermentation time, the proportion of raw materials (such as soybeans, wheat and salt), and the processing technology . Different types of soy sauce (such as light soy sauce, dark soy sauce, dark soy sauce, etc.) have different colors . Consumers usually judge the freshness, concentration and flavor of soy sauce by color :

· Light soy sauce : Generally light brown or amber in color, usually used in light dishes, and has a more transparent color.

· Dark soy sauce : dark brown or almost black, mainly used for coloring during cooking or to add rich flavor to dishes.

· Dark soy sauce : It is a specially prepared dark soy sauce with a very dark color. It is often used to color dishes and is usually a dark brown color close to black.

.jpg)

Why should you care about the color of soy sauce?

1. Consumer perception and purchasing decision

The color of soy sauce is one of the important bases for consumers to judge its quality. Soy sauce with bright and transparent color is generally considered fresh and high quality. On the contrary, if the color of soy sauce is too dark or uneven, it may leave consumers with the impression that the product is of poor quality or improper storage. Therefore, maintaining the consistency of soy sauce color is crucial to the brand image.

2. Reflect the brewing process and raw material quality

The color of soy sauce often reflects the characteristics of its fermentation process. For example, soy sauces that are fermented for a long time or made using traditional methods tend to have a darker and fuller color. On the other hand, soy sauces that use modern methods or artificially speed up the fermentation process may have a lighter color. Too short a fermentation time or improper selection of raw materials can also result in uneven or too light a color.

3. Production consistency and quality control

For large-scale soy sauce brands, color consistency is key to ensuring product quality and production stability. Any deviation in batch color may affect the product's market performance and consumer loyalty. Through precise color measurement, manufacturers can ensure that the color of each batch of soy sauce meets the standard and ensures consistency.

Factors Affecting Soy Sauce Color

The change of soy sauce color is the result of the combined effect of many factors. The following are the main factors affecting the color of soy sauce:

1. Raw material selection

The quality of soybeans and wheat directly affects the color of soy sauce. High-quality soybeans and malt can provide more natural pigments and promote color generation during the brewing process. Different varieties of soybeans and malt may bring different colors, and the proportion used and processing methods will also affect the final color.

2. Fermentation time and temperature

The temperature and time of the fermentation process have an important impact on the color of the soy sauce. The longer the fermentation time, the darker the soy sauce is usually, because during the long fermentation process, sugar substances will be converted into pigments. High temperature fermentation can also speed up this process, but if not controlled properly, too high a temperature may cause the color to be too dark.

3. Storage conditions

The storage conditions of soy sauce will affect its color stability. Storage in an overly humid environment or exposure to sunlight may cause the color to fade or darken. Soy sauce needs to be stored at the right temperature and environment to maintain its color stability.

4. Additives and preservatives

Some soy sauce manufacturers may add pigments or other additives to adjust the color. Caramel color is often used to increase the color depth of soy sauce and ensure its uniformity of color. However, excessive use of pigments may make the color of soy sauce unnatural, so the use of additives needs to be strictly controlled.

How to measure the color of soy sauce?

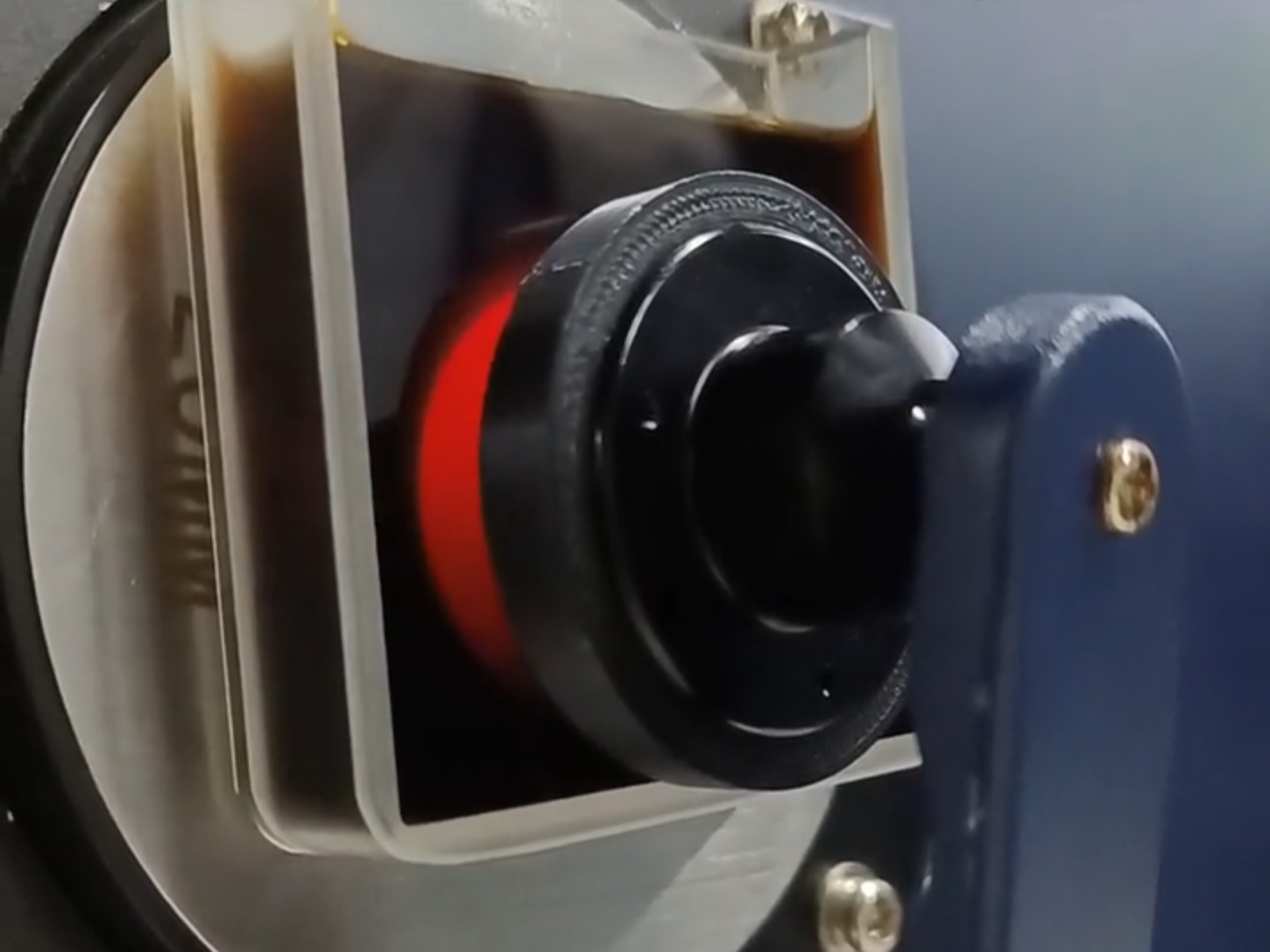

Soy sauce is usually liquid and translucent or opaque, so it is necessary to use reflected light or transmitted light measurement methods. It is recommended to use a professional spectrometer or colorimeter, such as the YS4560 Plus Spectrophotometer, which adopts a 45/0 geometric optical structure (45-degree annular illumination, 0-degree reception), which is suitable for measuring the surface reflected light of opaque or translucent samples. The following are the specific measurement steps:

1. Sample Preparation

Pour the soy sauce into a transparent sample cup or cuvette, making sure the liquid surface is flat and free of bubbles.

Control the sample thickness (1-2 cm is recommended) to ensure representative measurements.

2. Instrument Setup

Use the Φ8mm or Φ4mm measuring aperture of the YS4560 Plus and select the appropriate aperture according to the sample volume (Φ8mm for larger samples and Φ4mm for small samples).

Calibrate the instrument with a standard color plate before measuring to ensure data accuracy.

3. Measurement and recording

Place the instrument above the sample and measure reflected light or transmitted light (depending on the transparency of the sauce).

Record the Lab* value:

L value: lightness (degree of depth, dark brown soy sauce has a lower L value).

a value*: Red-green hue (positive values indicate reddishness, negative values indicate greenishness, soy sauce is usually reddish-brown).

b value*: Yellow-blue hue (positive value indicates yellowishness, soy sauce may have a slightly yellow component).

These values are analyzed to assess whether the soy sauce meets the target color standards.

4. Measurement environment

Avoid direct sunlight or strong light interference, and maintain stable indoor light and temperature (20-25°C is recommended).

If the soy sauce contains sediment, shake it thoroughly before measuring.

Common problems and solutions in measurement

Problem 1: Sample is turbid or precipitated

Effect: Sedimentation or inhomogeneities may interfere with color readings.

Solution: Gently shake the sample or remove the precipitate by filtration before measuring.

Problem 2: Uneven light reflection

Impact: Uneven liquid surface or bubbles can cause measurement deviation.

Solution: Make sure the sample surface is flat and use a scraper or tool to remove bubbles.

Soy Sauce Color Industry Standards and Regulations

The color of soy sauce must comply with food safety and quality standards, such as the International Food Codex (Codex Alimentarius) or local regulations of various countries (such as China GB 2717-2018 "National Food Safety Standard" Manufacturers should record color data to ensure that their products meet market access requirements. For example, some standards may specify that the Lab* value of soy sauce should be within a certain range to ensure that the color is as expected.

3nh Instrument Recommendations for Sauce and Condiment Color Measurement

In the production of condiments such as soy sauce , color consistency is crucial. To this end, it is essential to use professional equipment to measure the color of condiments. 3nh instruments are known for their high precision, stability and user-friendliness. They are widely used in the fields of color management and quality control. They can meet the needs of different industries for precise color measurement and data analysis, providing users with efficient and reliable solutions. The following are some of 3nh's recommended instruments for sauce and condiment color measurement.

|

Instrument Name |

Measuring geometry |

Applicable scenarios |

Features |

|

YS4560 |

45/0 |

Sauces, condiments, food quality control |

Portable, suitable for on-site measurement |

|

YL4560 |

45/0 |

sauces, condiments and production lines |

No contact with the sample, preventing damage to the sample and avoiding cross contamination |

|

YS6060 |

d/8 |

Sauces, condiments, opaque samples |

Versatile and suitable for a variety of industries |

|

TS8450 |

45/0 |

Color measurement of condiments, sauces, and foods |

Versatile and suitable for a variety of industries |

|

|

|

|

YS4560 |

YL4560 |

|

|

|

|

YS6060 |

TS8450 |

0086 18165740359

0086 18165740359

.png)

Skype Online

Skype Online