Industrial Coatings and Paint Color Detection

Industrial coatings are often applied to surfaces such as machinery , equipment, and metal structures. These surfaces require not only functional protection, but also must have a good visual appearance. The challenge of color detection is to maintain color consistency across different production batches, especially in harsh environments with high temperature, humidity, or chemical exposure. Industrial coatings play an important role in protecting and beautifying surfaces such as metals, machinery, and equipment, and color detection is a key link in ensuring the quality and consistency of these coatings. The color consistency of industrial coatings directly affects the appearance, durability, and market acceptance of the product. Inaccurate color formulas or color differences may lead to a decrease in coating performance, affecting functions such as corrosion protection and wear resistance. In the following areas, industrial coatings require color detection to ensure quality:

Heavy industry : Anti-corrosion coatings for large structures such as bridges, ships, and oil tanks require precise color control to ensure the visual effect and protective performance of the coating.

Automotive Manufacturing : For industrial coatings for automotive parts, color consistency is critical to ensure a uniform appearance and brand recognition throughout the vehicle.

Home appliances and electronic products : Industrial coatings are used to protect the outer shells of home appliances such as refrigerators and washing machines, and color testing ensures product aesthetics and brand image.

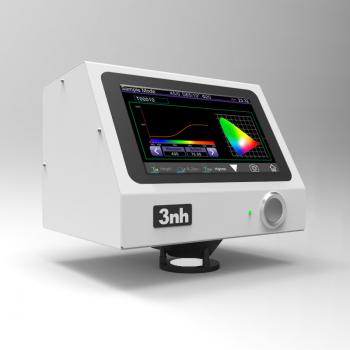

Using 3nh spectrophotometer and color matching software PeColor for industrial coatings and paint color testing, manufacturers can provide high-quality, durable and market-compliant coating products, enhancing product competitiveness and brand value.

0086 18165740359

0086 18165740359 346 Hits

346 Hits

2024-08-30

2024-08-30

Skype Online

Skype Online