In color measurement, geometry is a key factor in determining measurement accuracy and data comparability. Different measurement geometries affect how the instrument collects color information. Especially in reflected light measurement, the choice of geometry directly affects the sensitivity to surface properties such as gloss, texture, and roughness. This article will deeply analyze the two most commonly used measurement geometries: d/8 (diffuse/8°) and 45/0 (45°/0°), their working principles, applicable scenarios, and pros and cons comparison.

What Is Color Measurement Geometry?

Color measurement geometry refers to the spatial relationship between the angle of illumination of the light source and the angle of reception of the detector . Different geometries affect the response to gloss, surface texture, and directional reflection during measurement.

Common geometry types:

-

d/8 (diffuse/8°)

-

8/d

-

45/0 or 0/45

- Multi-angle

What Is Diffuse d/8 Sphere Geometry?

Definition

-

d = diffuse (diffuse light)

-

8 = 8° receiving angle

An integrating sphere was used to provide a uniform diffuse light source to illuminate the sample, and the detector was located at an angle of 8° to receive the reflected light.

.png)

Features

-

Diffuse reflection measurement : can effectively reduce the influence of sample surface gloss and texture on the measurement results;

-

Strong gloss compensation capability : can provide more stable color measurement results for high-gloss and uneven samples;

-

Wide range of applications : Suitable for measuring solids, liquids, powders, opaque or translucent samples.

-

Selectable gloss inclusion or exclusion (SCI/SCE ) mode :

SCI (Specular Component Included) : Includes specular reflection light

SCE (Specular Component Excluded) : Exclude specular light

Advantage

✔ Suitable for irregular surfaces

✔ Provides more objective color measurement results

✔ Commonly used in industries such as plastics, textiles, paints, powders, etc.

Shortcoming

⚠ There is a certain difference between visual color reproduction and human eye observation

⚠ The cost is slightly higher and the instrument structure is complex

What Is Directional 45/0 Geometry?

Definition

-

45° light source illuminates the sample

- for receiving reflected light at 0° angle

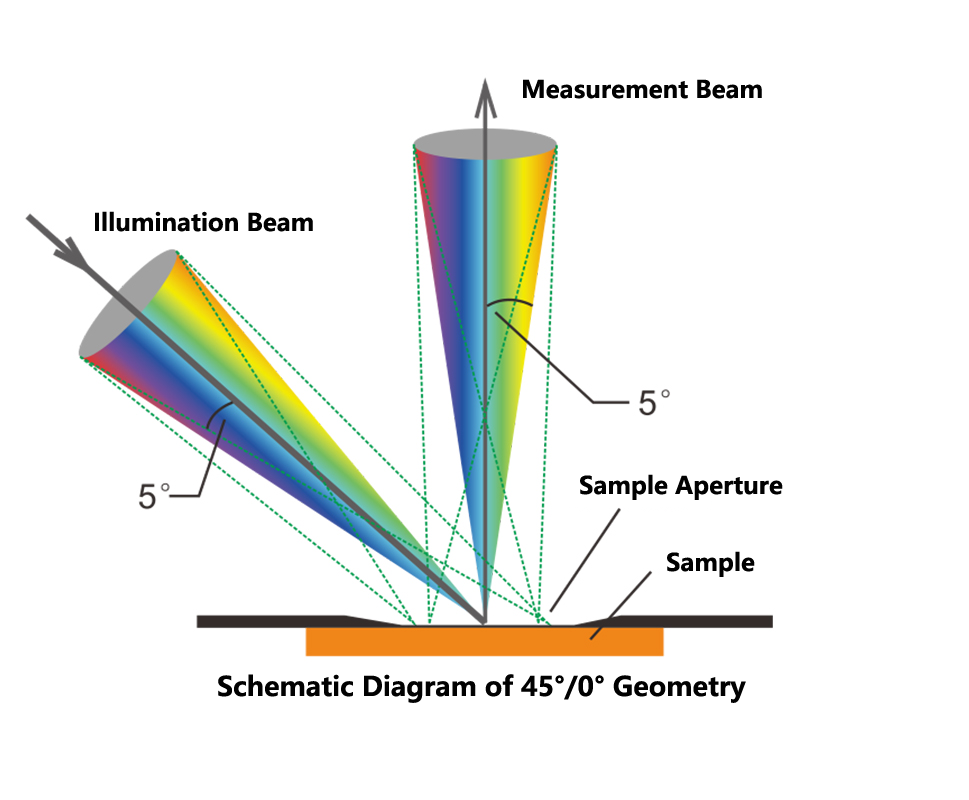

The 45/0 structure, the incident light hits the sample surface at 45° angle and the reflected light is measured from 0° direction , which is a directional light source - directional receiving structure.

Features

-

Simulate human vision : The measurement results are more in line with the actual colors observed by the human eye;

-

Sensitive to surface texture : can accurately measure the color and appearance changes of the sample surface;

-

Gloss Sensitive : Gloss changes on the sample surface can significantly affect the measurement results.

Advantage

✔ High visual consistency, closer to the perception of the naked eye

✔ Suitable for industries where visual effects are important, such as printing, packaging, fabrics, paper, color labels, etc.

Shortcoming

⚠ Sensitive to gloss and easily disturbed by surface texture

⚠ 0/45 Not suitable for highly reflective materials and special effect colors

d/8 vs. 45/0: Comparative Analysis

|

Comparison Dimensions |

Diffuse d/8 Sphere Geometry |

Directional 45/0 Geometry |

|

Light source type |

Integrating sphere diffuse light |

Directional Light |

|

Receiving Angle |

8° |

0° |

|

Gloss Effect |

Option to include or exclude gloss |

Very sensitive |

|

Applicable samples |

Various materials, uniform colors |

Clear surface texture, visual reproducibility required |

|

Consistency of measurement results |

High (less susceptible to texture distractions) |

Greatly affected by surface structure and gloss |

|

Commonly used in the industry |

Coatings, plastics, textiles |

Printing, packaging, paper products, food labels |

Recommended 3nh Color Measurement Instruments:

a. Recommended d/8 Structure Instrument :

3nh TS7708 Portable High Precision Spectrophotometer

Under the D8 geometric optical lighting conditions recommended by CIE, TS7708 spectrophotometer can accurately measure the SCI and SCE reflectance data of samples/fluorescent samples, and can accurately measure and express various color difference formulas and color indexes in multiple color spaces. With the help of the TS7708 spectrophotometer, accurate color transmission can be easily achieved, and it can also be used as a detection equipment for accurate color matching systems. It is also widely used in color difference quality control. The TS7708 is equipped with high-end color management software, which can be connected to a computer to achieve more functional expansion.

3nh TS8650 Desktop Spectrophotometer

The TS8560 desktop spectrophotometer adopts the internationally widely applicable D/8 lighting observation conditions and SCI/SCE (including specular reflection/excluding specular reflection) synthesis technology, and supports SCI+SCE simultaneous rapid measurement. It can be placed and measured in multiple postures such as side measurement, upward measurement, and downward measurement (using accessories), and the open transmission chamber can adapt to more samples to be measured.

b. Recommended 45/0 Structure Instrument :

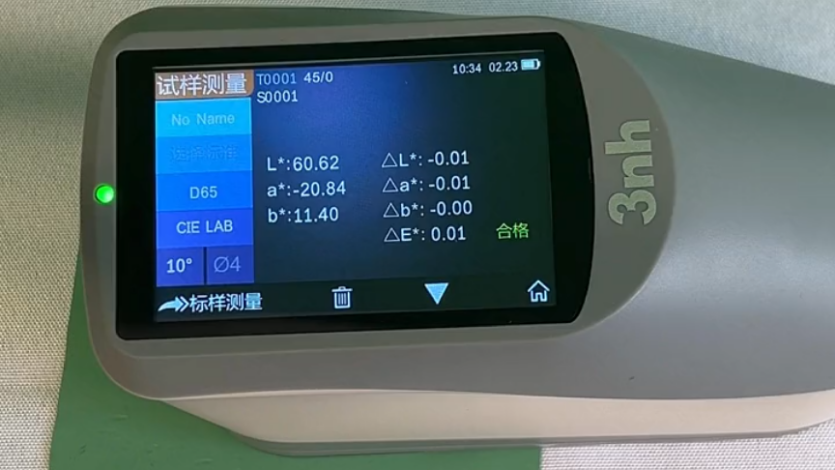

3nh YS4560 Portable Spectrophotometer

The YS4560 high-precision spectrophotometer adopts a 45/0 (45-degree annular illumination, 0-degree reception) geometric optical structure that complies with CIE No.15, and uses a concave grating spectrophotometer to accurately measure sample reflectance and various chromaticity data. The instrument is equipped with dual measuring apertures of Φ8 and Φ4mm, and is used for accurate color measurement and quality control in industries such as traffic signs, plastic electronics, paints and inks, textile and clothing printing and dyeing, printing, and ceramics. The instrument has a separate UV light source that can be used to measure fluorescent samples. The instrument has built-in GB 2893 and GB/T 18833 standard colors, and can manually customize polygonal rectangular tolerances, and one-click measurement of the brightness factor and chromaticity coordinates of traffic signs, markings, and reflective films.

Desktop Spectrophotometer TS8450

TS8450 is a desktop spectrophotometer with 45/0 optical structure. The instrument repeatability ΔE*ab is easily controlled within 0.02, and the inter-instrument difference ΔE*ab is controlled within 0.15. It is accurate in measurement and can be used for accurate color analysis and transmission in laboratories. TS8450 portable desktop spectrophotometer is suitable for the measurement of brightness factor and chromaticity coordinates of traffic signs, markings, and reflective films. It contains GB 2893 and GB/T 18833 standard colors, and can manually customize polygonal rectangular tolerances.

0086 18165740359

0086 18165740359 Skype Online

Skype Online