2. What factors affect color consistency?

3. Why is color consistency so important?

4. How to maintain color consistency

5. 3nh’s color consistency solution

1. What is color consistency?

1.1 Definition and basic concepts of color consistency

Color consistency refers to the ability of a product’s color to remain constant across batches, lighting conditions, or materials. This consistency is critical to consumers’ brand perception and user experience, so color consistency is a key indicator in production, design and brand maintenance.

Color consistency is widely used in advertising, clothing, printing, packaging and other fields. In visual communication, color consistency helps maintain the brand image and ensure consumers' trust in the product. For example, inconsistent colors on packaging may affect consumers' purchasing decisions.

Maintaining color consistency requires the use of measurement, calibration and standardization tools to ensure color stability by controlling multiple factors such as light sources and materials. Color consistency usually relies on devices such as colorimeter and spectrophotometer for precise measurement and management.

2. What factors affect color consistency?

2.1 Effects of different light sources on color consistency

The color rendering effect under different light sources (such as sunlight, fluorescent light, LED light, etc.) will be different, which is called "metamerism". By controlling the light source of the test environment, the color difference caused by light changes can be reduced and the consistency of color under different lighting conditions can be ensured.

2.2 Effects of material and surface properties on color

The reflection, absorption, and scattering properties of a material have a significant impact on color. For example, smooth surfaces are usually more colorful than rough surfaces, so different materials and surface treatments can result in different color performances.

2.3 Impact of environmental factors, temperature and humidity

Factors such as ambient temperature and humidity affect the color performance of materials to a certain extent. For example, under high temperature conditions, some coatings may be yellowish in color. Therefore, materials and products used in different environments should be tested for temperature and humidity to ensure consistency.

2.4 Human interference

Color errors may be caused by human factors, such as failure to follow standards during production and lack of operator experience. Therefore, it is particularly important to establish standardized processes and personnel training.

3. Why is color consistency so important?

3.1 Advertising and Marketing: Improving Brand Image

Color consistency is crucial in branding and advertising design. Inconsistent colors may lead to a decline in brand recognition and affect consumers' loyalty and trust in the brand.

3.2 Clothing and textile industry: ensuring product quality

In the apparel and textile industry, color consistency directly affects the quality of finished products. Color differences in clothing not only cause complexity in inventory management, but may also cause returns. Therefore, strict color control can help reduce costs.

3.3 Electronic display devices: achieving visual consistency

For display devices such as mobile phones and TVs, screen color consistency affects the user experience. Accurate color management ensures that the device can display the same color effect under different batches and light source conditions.

3.4 Packaging and Printing Industry: Improving Consumer Experience

In packaging and printing, color consistency helps strengthen brand identity and makes products more attractive on the shelf. Consistent packaging color conveys a sense of reliability and high quality, helping to increase consumer trust.

4. How to maintain color consistency

4.1 Establishment of Color Management System

Establishing a color management system (CMS) can make the color information of multiple processes such as design and production consistent, which is easy to track and control. Using consistent color data in the production chain helps reduce errors.

4.2 Calibration and use of standard color cards

Color cards such as PANTONE and RAL provide standard color comparisons to ensure color consistency in each production and design link. By comparing with color cards, designers, suppliers and manufacturers can ensure color matching.

4.3 Use consistent lighting and light source conditions

When measuring color and displaying products, it is recommended to do it under uniform lighting conditions to avoid color differences caused by light source changes. Standardized light source settings can better present the true color of the product.

4.4 Regular color measurement and data recording

Regular color measurement can detect color deviations and correct them in time. Recording measurement data and generating reports can help maintain long-term color consistency.

5. 3nh 's color consistency solution

As a leading color management solution provider, 3nh 's rich product series are widely used in various industries, helping companies maintain color consistency in various production and testing scenarios. Through high-precision color measurement equipment, standard light source color matching light boxes and professional color management software, 3nh can help you effectively improve the efficiency and accuracy of the color management process.

5.1 3nh color detection equipment

3nh provides a variety of color detection equipment, including portable colorimeter, spectrophotometer and multi-angle colorimeter. These devices are widely used in textile, printing, automotive, plastic and other industries, and enable enterprises to monitor and adjust color consistency in real time during the production process by accurately measuring the color difference value of materials.

· Portable colorimeter : light and easy to operate, suitable for on-site measurement, can quickly detect color differences, and is convenient for personnel from all departments to use.

· Spectrophotometer : High-precision spectrophotometer can accurately detect the spectral reflectance of materials and is suitable for industries with high color requirements, such as coatings, electronic displays, etc.

· Multi-angle colorimeter : suitable for detecting color changes of special coatings or surface materials, helping to analyze color performance at different angles.

These color measurement devices can provide color difference data and color standard comparison capabilities to ensure color consistency across multiple batches and lighting conditions.

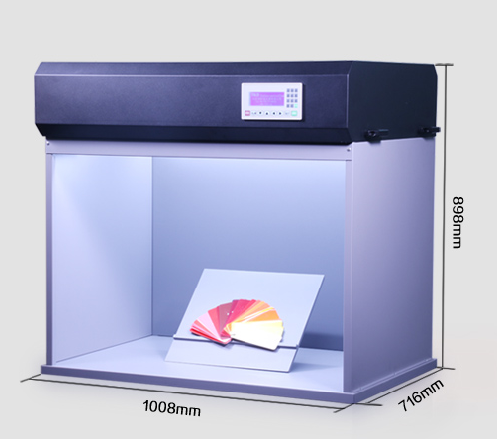

5.2 3nh standard light source color matching light box

3nh's standard light source color matching light box is a color measurement tool that provides a variety of light source conditions and can simulate different lighting environments, such as daylight, tungsten lamps, fluorescent lamps, etc. The standard light source light box unifies the lighting environment, effectively reduces the impact of light source changes on color consistency, and ensures consistent color presentation under different light sources.

· Multiple light source options : 3nh's light box can provide a variety of light source types to meet the testing needs of multiple industries. Common light sources include D65 (daylight), TL84 (commercial lighting), UV, etc.

· Convenient for batch testing : The color matching light box allows samples from different batches to be compared under the same light source conditions, which is suitable for quality testing in industries such as packaging, clothing, and plastics.

· Improve detection efficiency : The light box is equipped with an automatic timing function to facilitate recording and monitoring the light source usage time, ensure the stability of the light source, and improve detection efficiency.

The standard light source color matching light box can effectively eliminate the color deviation caused by inconsistent light sources and is one of the key tools to maintain color consistency.

5.3 3nh Color Management Software

3nh color management software PeColor is a comprehensive color data management tool that can be seamlessly connected with 3nh's color measurement equipment to provide comprehensive support from color data collection, comparison, analysis to report generation. The color management software helps users establish and manage standard color data to achieve color consistency control.

· Data collection and comparison : The software can quickly read device data and provide color comparison function, so that users can analyze and adjust color difference problems in the production process in real time.

· Automatically generate reports : Color management software supports automatic generation of color consistency test reports, making it easier for companies to record and save color data and improve the accuracy of color traceability and records.

· Personalized settings and remote collaboration : The software provides personalized parameter setting functions, and can customize color management standards according to different industry requirements. At the same time, the software supports data sharing, which facilitates multi-department collaboration.

3nh's color management software helps users better control and manage color consistency by integrating color measurement instrument data, thereby significantly reducing production errors and improving production efficiency.

0086 18165740359

0086 18165740359 Skype Online

Skype Online