Cotton is one of the world's most important crops, its main by-products have high utilization value. Cotton is the most important fiber crop, but also an important oil crop, but also contains high protein food crops, or textile, fine chemical raw materials and important strategic materials. United States Department of Agriculture (USDA) grading standards is an important reference standard for the international cotton market. In addition to the United States, China and India are also the world's major cotton producers, and developed their own color grading standards. This article will focus on the characteristics of China, the United States and India's cotton color grading standards, and combined with practical applications, recommend a more efficient to meet a variety of international standards of the 3nh standard light source products, to help enterprises to improve the accuracy and consistency of the cotton grading inspection.

1. United States Standards (USDA)

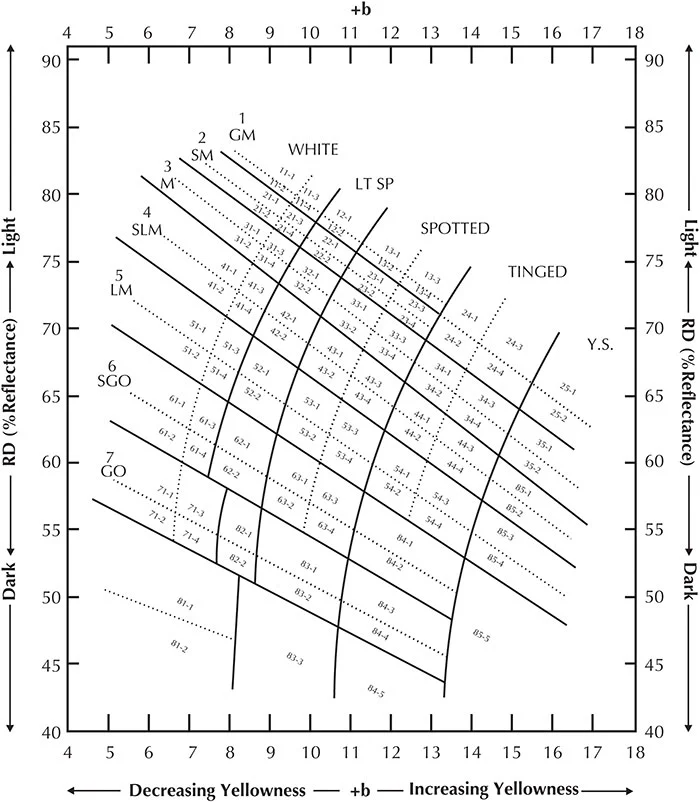

The U.S. Department of Agriculture (USDA) standard, which classifies cotton color into several grades based on Color Grade, Reflectance (Rd), and Yellow Index (+b), is fully automated with a High Volume Instrument (HVI).

1. Color Grade: Describes the overall color appearance of cotton, ranging from white to gray and yellow.

2. Reflectance (Rd): Indicates the brightness of the cotton surface; the higher the reflectance, the whiter the cotton.

3. Yellow Index (+b): Measures the concentration of yellow components in cotton, the higher the index, the more yellowish the color.

According to these parameters, cotton color is divided into several grades, divided into White, Light Spotted, Spotted, Tinged, Yellow Stained, Light Gray and Gray, and other seven color grades, different grades are suitable for different applications. Different grades are suitable for different applications.

Features:

· Focus on the measurement of objective parameters (e.g., reflectance and yellow index).

· Highly data-driven grading using the HVI system.

2. Chinese standard

Cotton can be divided into four categories according to its color: white cotton, light spot-stained cotton, light yellow-stained cotton, and yellow-stained cotton. The division of cotton color type, mainly dependent on the degree of yellow in the cotton sample. Normal cotton has a white or cream background color, such cotton is white cotton type. Since the cotton fiber in the immature period due to frost or dry early, insect pests and dead cotton fibers appear dark yellow, so the more such fibers contained in the cotton, the more yellow and dark color. Another cause of the yellow color of cotton is the storage of lint. The degree of yellowing fibers depends on the storage temperature, humidity and the length of storage time.

1. White cotton

Generally refers to the normal growth in normal weather, mature or over-mature cotton fiber. This type of cotton mainly highlights the "normal", in all the factors affecting the color of cotton are basically normal when the cotton is classified as white cotton, giving people the color sense of white, gray, creamy white, there should not be yellowish, yellowish feeling.

2. Lightly stained cotton

White cotton mixed with some in the immature period due to frost or drought, insect damage and death of yellowing fibers, or due to light pollution and long-term storage of yellowing fibers, that is, white cotton mixed with part of the supine cotton, or white cotton due to light contamination or excessive moisture caused by the overall color of the fiber yellowing.

3. Yellowish dyed cotton

A variety of stiff petal cotton and part of the late sub-cotton, contaminated cotton, rotten peach cotton, or light spot stained cotton mutation. This type of cotton is rarely seen in normal circumstances, mostly for the processing of white cotton separated from the cotton and cotton pollution composition.

4. Yellow dyed cotton

New cotton is almost impossible to find this kind of cotton, in special circumstances will appear, for many years of storage variation, or back to a large rate of seed cotton, did not dry in time to turn yellow.

Features:

· Combination of manual and instrumental testing with more reliance on human experience.

· Color grading focuses more on the visual appearance of the cotton.

3. Indian Standard

India has not established a systematic cotton quality grading standards, mainly based on varieties and sensory inspection (color, impurity, ginning quality) for rough classification.

The main high-grade varieties: Shankar-6, MCU-5, DCH32, etc., are recognized by the international market as medium and high-grade cotton due to better fiber length, strength and other indicators.

Grading terminology: Use vague descriptions such as "Extra Super Fine", "Super Fine", "Fine", "Good", etc., and allow the addition of "Half" grades between full grades (e.g. half a grade between Fine and Super Fine). "Good", etc., and allow the addition of "Half" grades between full grades (e.g., half a grade between Fine and Super Fine).

Features:

· The appearance color and purity of the cotton are the main indicators.

· Manual grading is still the primary method, and machine grading is gradually gaining popularity.

What light source is used for color grading cotton?

Cotton grading is an important part of cotton quality evaluation, in which the evaluation of cotton color, luster, fiber quality and other aspects is key. In order to ensure the accuracy and consistency of these evaluations, the need to use a standard light source in line with international standards for inspection. In the cotton classification, the current commonly used light source is the D75 light source.

D75 light source is a simulation of the northern average sunlight standard light source, its color temperature is 7500 K. Because daylight varies with climate and time, the color temperature of the light source in the 5500 ~ 7500 K between changes. Color temperature that is the light source color quality characterization. The color quality of the light source, that is to say, to understand the light of a light source of the chromatic tendency and the degree of color saturation. Technically, we use color temperature (K) to indicate the color quality of the light source. For the color temperature and the color quality of the light source, there can be such a view, the higher the color temperature, the cooler the light, the lower the color temperature, the warmer the light.

Simply put, D75 light source is also a standard light source that simulates daylight. With the domestic commonly used D65, D50 is mainly the difference in color temperature.

Cotton color grading light box

D75 cotton grading standard light source box is a cotton grading room simulation daylight lighting device for cotton inspection and grading room to assess the cotton color and other similar occasions, instead of the traditional north-facing skylight daytime light, more stable than the natural light, to overcome the geographical location, seasonal time, weather conditions and other factors, day and night can work to improve efficiency. The light box is all processed by CNC machine tools, with beautiful appearance and good size consistency. Installation is simple and maintenance is convenient.

The equipment complies with IS04911 and the national standard GB/T13786-2022 "Simulated Daylight Illumination of Cotton Grading Room", and has the following advantages:

1. Accurate/stable: using LED lamp beads light source, beyond the national standard D75 light source, no spectral peaks more accurate and stable color rendering!

2. Light intensity selection key by heart: with high color rendering power index and join the adjustment of light intensity remote control facilities, a key to adjust the light intensity, do not fear attenuation more intimate!

3. Illumination doubled strong: common light source lamp observation surface illumination 750 ± 100LX, LED light source lamp up to 750 ~ 1600LX illumination is more prominent!

4. Four times the service life: common fluorescent light source in the use of 2000 ~ 3000 hours after the attenuation, LED light source lamp up to 13000 hours!

5. Comfortable / efficient: LED DC power supply, no strobe, goodbye to fluorescent light source strobe trouble, significantly reduce the fatigue of the inspectors work, inspection time comfortable and more efficient!

0086 18165740359

0086 18165740359

Skype Online

Skype Online