Grain color is an important indicator for assessing grain quality, maturity, and suitability for processing. Accurate color measurement ensures standardization in agricultural production, food processing, and supply chains. In this article, we will explore when to measure grain color and how to achieve accurate color measurement. The best way to measure.

When to Measure Grain Color

Measuring grain color is not always necessary, but evaluating grain color is particularly important in the following scenarios:

1. Decide when to harvest

Why it matters: Grain color is a direct reflection of ripeness. For crops like wheat, rice, and barley, subtle changes in color can indicate the best time to harvest.

Example: When rice is golden yellow, it is ripe, while green means it is not yet ripe. 3nh spectrophotometer has the function of testing yellowness, which can measure whether the color of grains meets the standard anytime and anywhere.

2. Quality control during processing

Why it’s important: In grain processing, such as milling or malting, maintaining color consistency is critical to the uniformity of the final product.

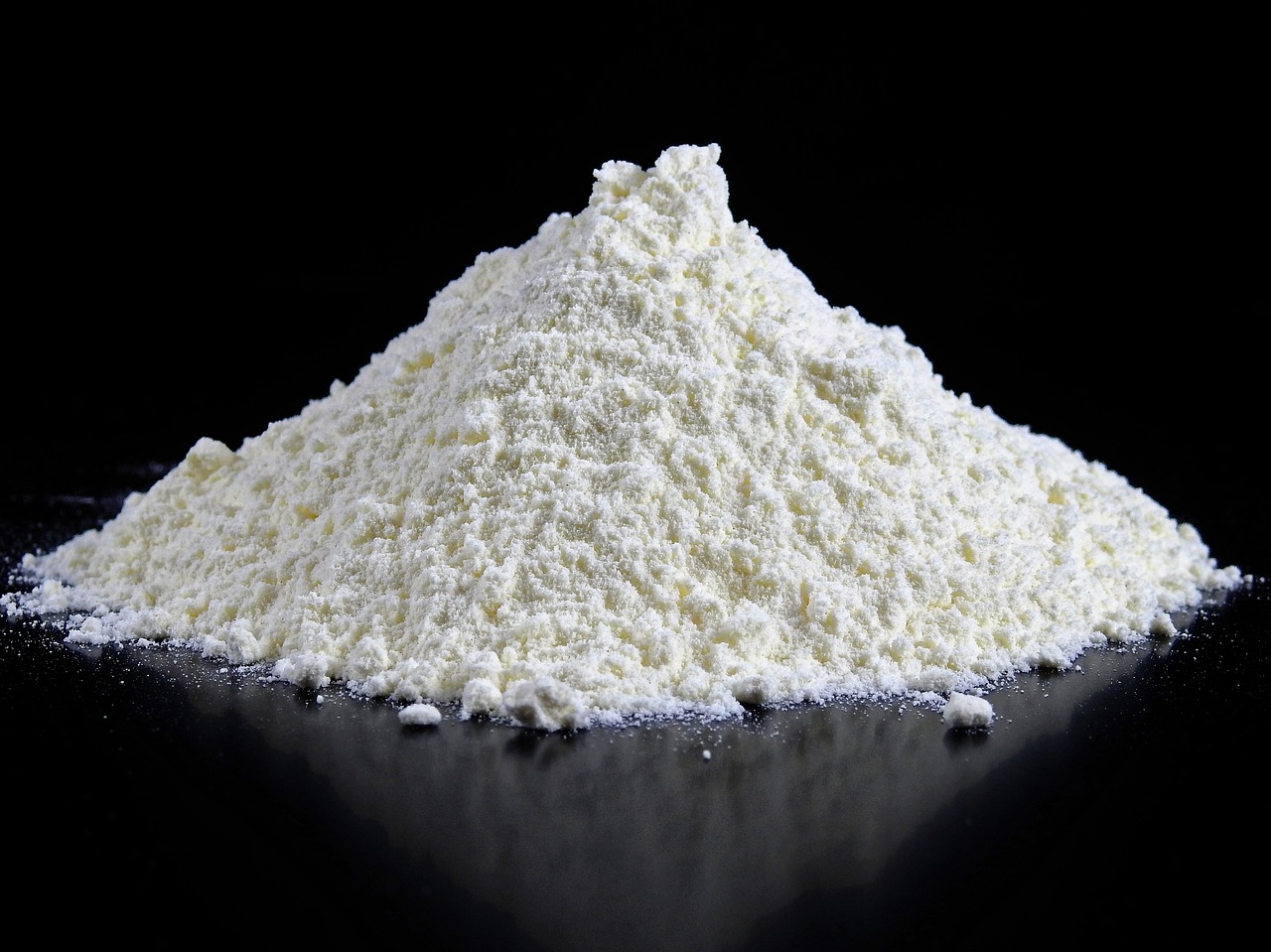

Example: Light-colored flour from high-quality wheat is more popular in the market. 3nh spectrophotometer has the function of detecting whiteness, which can detect whether the flour meets the standard.

3. Detect contamination or deterioration

Why it matters: Unusual grain color may reveal contamination, mold, or pest problems.

Example: Dark spots or discoloration on grain may indicate mold infection or insect infestation.

4. Market grading and pricing

Why it matters: Grain is often graded and priced based on quality parameters, including color.

Example: Brighter grains tend to fetch higher prices in the market, especially commodity crops like corn and sorghum.

5. Comply with industry standards

Why it matters: Regulatory agencies often set standards for cereal color to ensure product quality and consumer trust.

Example: Export grade grain needs to meet color consistency requirements to comply with international trade regulations.

Methods for measuring grain color

There are many ways to measure grain color, from traditional manual methods to advanced digital solutions, and the right technology should be selected based on specific needs.

1. Manual inspection

Procedure: Check grain color visually under natural or artificial light.

Tools: Reference color cards or color samples.

Advantages: low cost , suitable for small-scale evaluation.

Disadvantages: Highly subjective and susceptible to human error. Not suitable for large-scale grain testing.

2. Digital Image Analysis System

Process: Grain color is captured and analyzed using a high-resolution camera and image processing software.

Advantages: High accuracy and consistent results. Suitable for large-scale operations.

Disadvantages: High initial investment cost.

3. Spectrophotometer detection

Process: Determines the color characteristics of grains by measuring the absorption and reflection of light.

Advantages: Quantitative data output, accurate and reliable. Able to detect tiny color differences.

Disadvantages: high cost, and requires skilled personnel to operate.

.jpg)

4. Portable colorimeter

Process: Use portable devices to measure color parameters (such as RGB, Lab*) and output the results instantly.

Advantages: Simple operation, easy to carry, suitable for on-site measurement.

Disadvantages: Limited analysis range, can only detect surface color.

Grain color measurement is an important tool for ensuring grain quality and market competitiveness. From traditional manual inspection to AI-based systems, a variety of methods meet different needs of scale and accuracy. Knowing when and how to measure grain color can help farmers and companies optimize harvests, meet quality standards, and maximize profits.

0086 18165740359

0086 18165740359 Skype Online

Skype Online