Color is a factor that cannot be ignored in the production and sale of pet food. Through accurate color measurement, manufacturers can ensure the consistency, quality and market appeal of their products. This article will comprehensively explore the importance of pet food color measurement, the factors that influence it, and how to use modern technical tools for accurate testing.

What are Pet Foods?

Pet food is a special food for domestic pets, which is usually divided into two categories: dry food and wet food. According to the type of pet (such as cats, dogs, etc.) and their nutritional needs, there are many types of pet food, which can be divided into the following categories:

· Kibble : This is the most common pet food, especially dog food. Kibble is made by drying or freeze drying, and its nutritional content is stable and easy to store.

· Canned Food : Canned food usually contains more water and has a richer taste, making it suitable for some picky eaters or elderly pets.

· Freeze-dried food : This type of food retains the nutrients and taste of the raw materials, but is more durable than wet food.

· Natural/organic pet foods : These foods typically use natural ingredients with no additives, providing purer nutrition.

In addition to the common types mentioned above, pet food also includes food for specific health needs (such as weight loss food, sensitive stomach food, etc.). As pet health awareness increases, consumers pay more attention to the quality and nutritional content of their pet food choices.

Why You Should Care About Pet Food Color

The color of pet food is more than just cosmetic appeal; it actually reflects the quality of the product and the stability of the process. Here are a few important reasons to pay attention to the color of pet food:

1. Color and quality association

Variations in color can mean different quality ingredients in pet food. For example, if the color of the food is inconsistent, it may reflect changes in certain ingredients in the recipe or problems with the processing. Uniform, natural color usually means good quality and standardized processing.

2. Consumer purchasing decisions

When consumers buy pet food, they are often attracted by the color first. For most people, bright and uniform colors represent freshness and high quality. If the color of pet food is inconsistent, it may cause consumers to question its freshness, which will affect their purchasing decisions.

3. Related to nutritional content

The color changes of some pet foods are closely related to their ingredients and nutritional value. For example, cat food rich in carotene may appear orange, while dog food rich in iron may be reddish. Color measurement can effectively evaluate the stability of nutritional ingredients.

4. Ensure product consistency

Large-scale pet food production needs to be consistent in color, especially branded products. Uniform color not only enhances the brand image, but also ensures that consumers can enjoy the same quality products every time they buy.

Factors Affecting Pet Food Color

The color of pet food is affected by many factors, including raw material selection, processing technology, storage conditions, etc. Understanding these influencing factors will help to better control product quality.

1. Raw material selection

Different raw materials have different natural colors. For example, vegetable ingredients such as carrots and spinach often give food an orange or green color; while some meats such as chicken and beef are yellow or brown. The freshness, source and ratio of the raw materials will directly affect the color of the final food.

2. Processing method

During the processing of pet food, changes in temperature, humidity and time can affect the stability of color. For example, food baked at high temperatures for a long time may change color and appear darker. Excessive heating can even cause certain pigments to decompose or uneven color.

3. Storage and transportation conditions

The storage environment of pet food, such as temperature and humidity, will also affect the color. High temperature or high humidity environment can easily cause food to fade or deteriorate. Therefore, reasonable storage and transportation conditions are crucial to ensure the consistency of pet food color.

4. Food additives

Sometimes, to make food more appealing, manufacturers may add pigments or natural colorants. While this method can enhance the visual effect, it can also result in colors that are too bright or unnatural if not added properly. Therefore, maintaining the proper use of additives is key to ensuring natural colors.

Measuring Pet Food with 3nh Spectrophotometer

The YL4568 spectrophotometer can also play an important role in measuring the quality control of pet food. This instrument adopts the 45/0° (45° annular uniform illumination, 0° reception) standard to provide accurate color measurement. The design of non-contact testing of the test probe and the sample under test makes it very suitable for color detection of pet food in different forms such as liquid, sauce, powder, etc. Due to its simple probe design, the YL4568 spectrophotometer can be easily integrated into the automated production line for accurate color measurement and color quality control. This instrument can ensure color consistency in pet food production, monitor whether there is excessive use of pigments or additives, and can also cope with color changes during food processing. It is widely used in many industries such as cosmetics, fruits and vegetables, food hygiene, plastic electronics, paints and inks, printing, ceramics, etc., and can measure fluorescent samples. The unique innovative design of the YL4568 not only provides non-contact measurement solutions directly from the production line, but also guarantees stable and high-precision measurement results to help ensure the quality and safety of pet food.

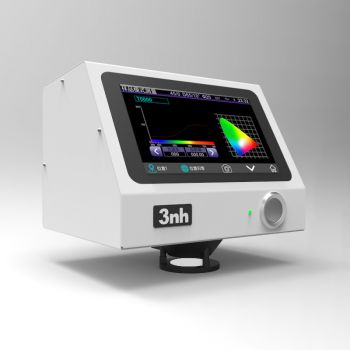

TS8450 is a desktop spectrophotometer with 45/0 optical structure. It adopts 256-pixel dual-array CMOS image sensor and imported white board, taking into account both measurement speed and operation convenience. The instrument repeatability ΔE*ab is easily controlled within 0.02, and the inter-instrument difference ΔE*ab is controlled within 0.15. The measurement is accurate and can be used for precise color analysis and transmission in the laboratory. It can perform non-contact measurement of pet food and conduct refined color analysis.

0086 18165740359

0086 18165740359

Skype Online

Skype Online